History

The Lipe Clutch brand has a rich heritage dating all the way back to the late 19th century. In 1880 the brand’s namesake, Charles E. Lipe, set up the Lipe Shop in the city of Syracuse, USA. Charles Lipe was a graduate mechanical engineer and prolific inventor, having invented and patented a hand corn planter whilst still in his teens. This ultimately became one of a whole range of speciality machinery the Charles Lipe manufactured in his own shop. Space in the shop was also rented out to other inventors, creating a loosely knit organisation of creative entrepreneurs which generated a flood of new ideas.

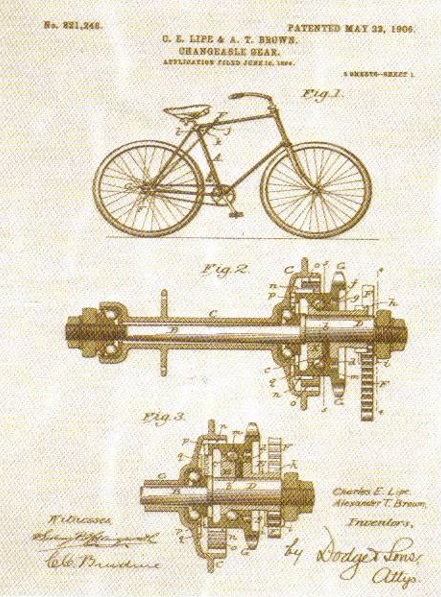

By the 1890’s the entire nation was in the grip of a bicycle craze. Among the major problems that cyclists faced at the time was the business of getting up hills without monumental effort and getting down them without losing control. A specialised gear mechanism was called for, just the type of challenge welcomed by the Lipe Shop. Charles Lipe went on to patent the Bi-Gear, a changeable bicycle gear with two speeds that enjoyed great popularity for several years but was eventually eclipsed by the advent of the coaster break.

That early bicycle gear not only upgraded bicycle performance dramatically; it also lead directly to the far more significant development of an automobile gear which was to become the world’s leader.

Early in the twentieth century, the bicycle craze of the nineties has given way to automobile-mania. As the Lipe Shop saw it, the skills were there, the experience was there; all that remained was to translate bicycle gears, with which the employees were familiar, into automobile gears. One automobile manufacturer who came to have parts for his first car built was Henry Ford. He himself arrived to oversee the job, and spent a substantial amount of time supervising production of the parts. Thus the famed Ford Model A joins the roster of technological achievements that can be traced back to the Lipe Shop. In fact, almost every mode of transport today is indebted in some way to the pioneering work done in this one remarkable shop in Central New York State.

The commercial vehicle clutch division of Lipe was formally established in 1932, with the introduction of the Lipe multiple level (ML) clutch. By 1935, Lipe had all of the General Motors Truck and Coach Division clutch business. Lipe rapidly grew to become a leading brand of heavy duty clutch components across North America.

Lipe Clutch was successfully introduced to the European market in the early 1970s via the establishment of a factory and engineering facility in Haslingden, England. Within a short time, all UK truck manufacturers were customers for both OEM equipment and service replacements. Since then, truck manufacturers in continental Europe, Africa, and the Middle East were added to the growing number of satisfied customers. Manufacturing continues today at the Haslingden factory, with a particular focus on the supply of aftermarket truck clutches for European applications, as well as manufacturing heavy duty clutch systems for either niche or high volume OEM applications.

The global expansion of Lipe Clutch manufacturing continued into India in 2000, with Setco signing a technical collaboration to manufacture Lipe Clutches for sales into Tata Motors. The sales in India grew rapidly, with Lipe Clutch becoming OEM fitment for many major Indian commercial vehicle manufacturers including Ashok Leyland, BharatBenz and Volvo–Eicher amongst others. The collaboration become so successful that Setco went on to acquire the Lipe clutch brand and global manufacturing facilities in 2005.

Today, Lipe Clutch has an established market across an extensive global network of 64 countries, spread across Europe, North Americas, South America, Latin America, Africa, Middle East and Asia Pacific. We continue to have a strategic global footprint with manufacturing facilities in the UK, USA and India. Lipe Clutch has set up a state of the art R&D centre at Kalol, India, certified to design, develop and validate full clutch systems, and also has a research and development centre in the UK. In addition, Setco also manufacturer hydraulic products for the construction equipment industry and precision engineering components like complex and deep drawn pressings, forgings, and castings that are machined and heat treated.

Lipe clutch has grown from its humble beginnings to manufacture over 50,000 medium duty and heavy duty commercial vehicle clutches each month, placing us among the top 3 manufacturers in the world by volume.